by Caoimhe Fullen | Jan 2, 2024 | News |

Following the introduction of the government’s revised Building Regulations Document B in 2019, mandating more rigorous fire safety measures, specifiers have been required to find solutions that meet the new Class A1 non-combustible standards. IG Lintels looks into...

by Caoimhe Fullen | Nov 28, 2023 | News |

IG’s award winning and BBA approved Hi-therm+ Lintel has evolved. This low-cost solution for reduced carbon emissions has upgraded insulation that delivers a 20% improvement in thermal perfromance, ensuring Hi-therm+ leads the pack when it comes to construction...

by Caoimhe Fullen | Nov 17, 2023 | News |

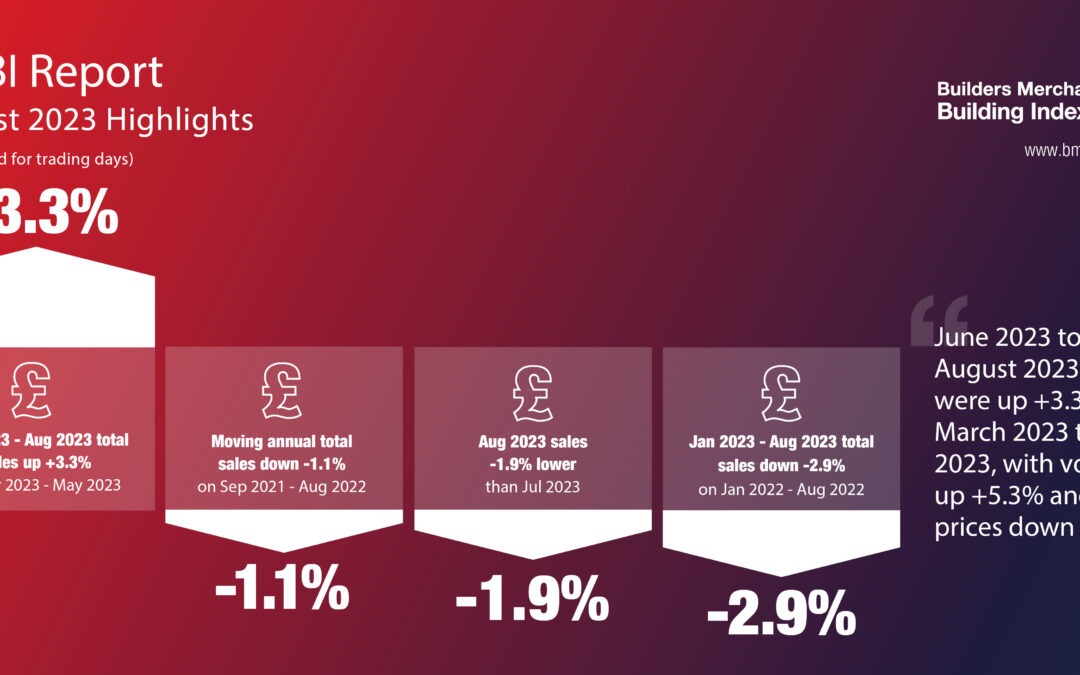

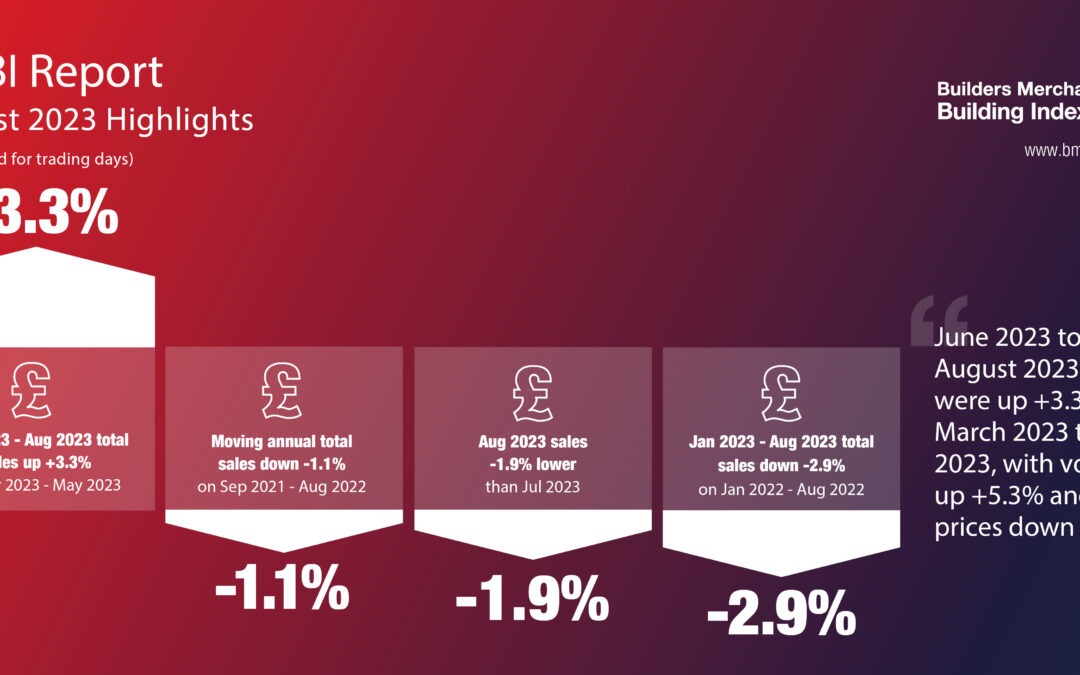

June to August Builders Merchant volumes up +5.3% on previous 3 months in the BMBI Report Q3 The latest Builders Merchant Building Index (BMBI) report shows builders’ merchants’ value sales were down -3.3% in the month of August compared to the same month in 2022,...

by Caoimhe Fullen | Nov 6, 2023 | News |

IG Lintels and the wider Keystone Group steel division have joined forces with other key influencers in the construction sector to provide a day of inspiration for Swift Brickwork Contractor‘s new cohort of brickwork apprentices. The highlight of the day was a tour of...

by Caoimhe Fullen | Oct 2, 2023 | News |

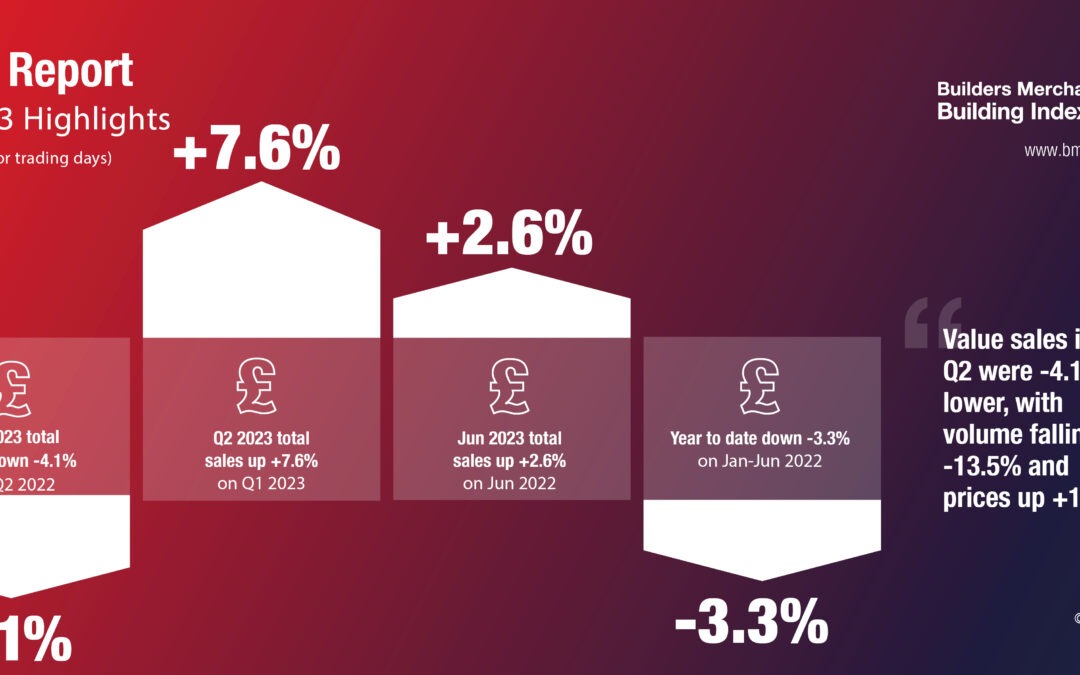

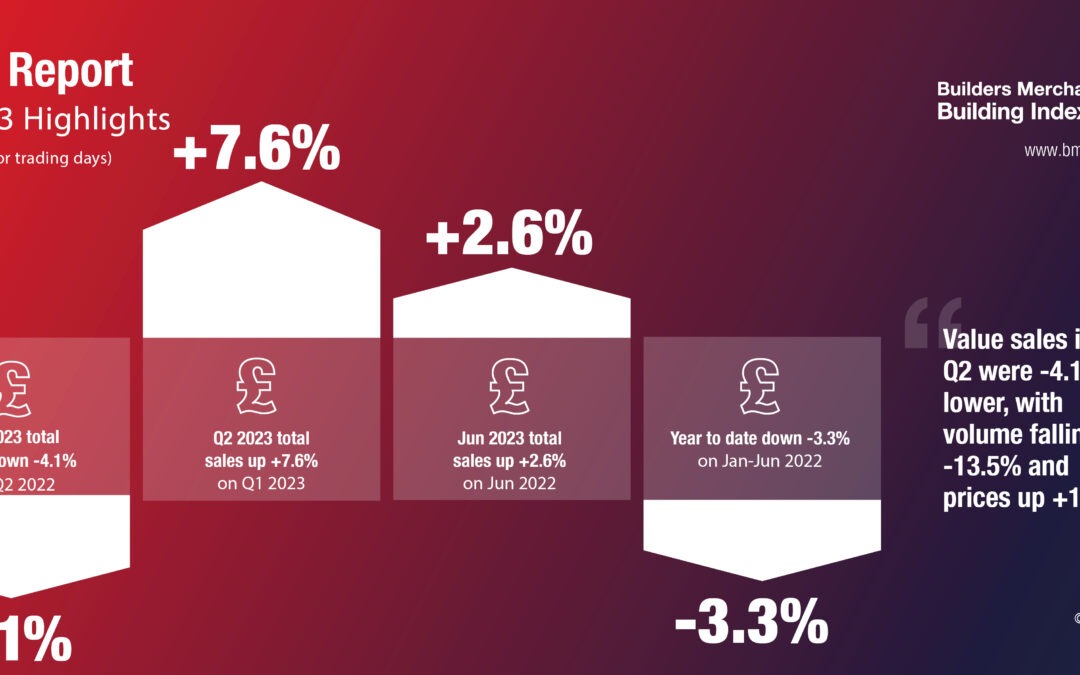

Q2 value sales up +7.6% on Q1, with volume up +11.3% and prices down -3.3% Quarter-on-quarter, total value sales from Britain’s Builders’ Merchants climbed +7.6% in Q2 2023 compared to January to March 2023. Growth came from stronger volumes (+11.3%) as prices were...

by Caoimhe Fullen | Aug 15, 2023 | News |

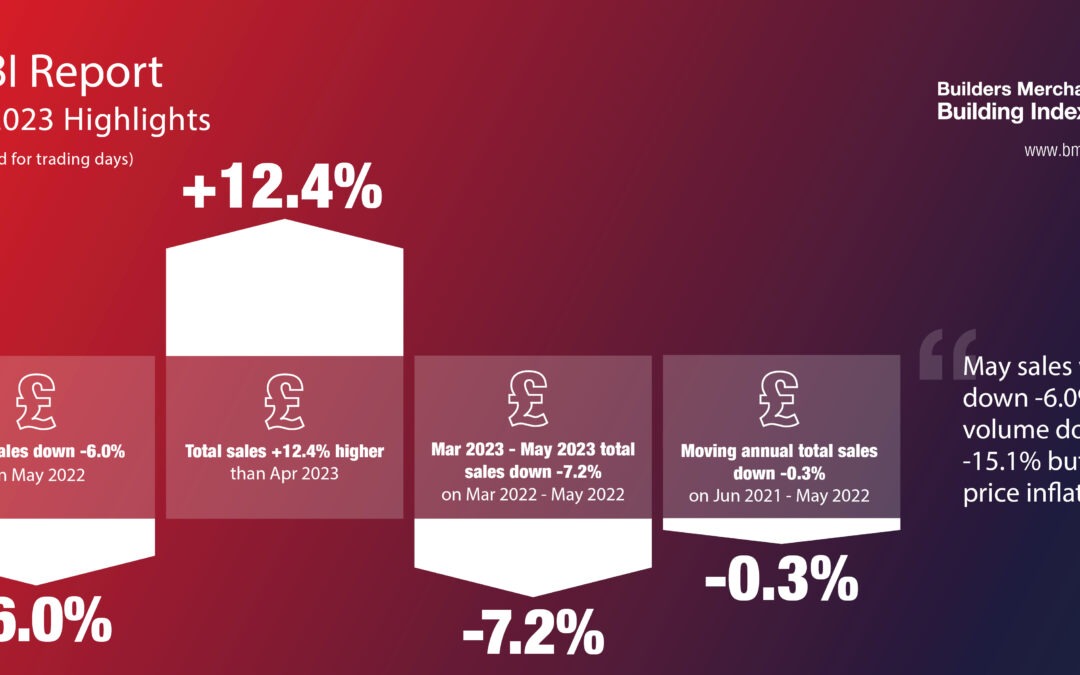

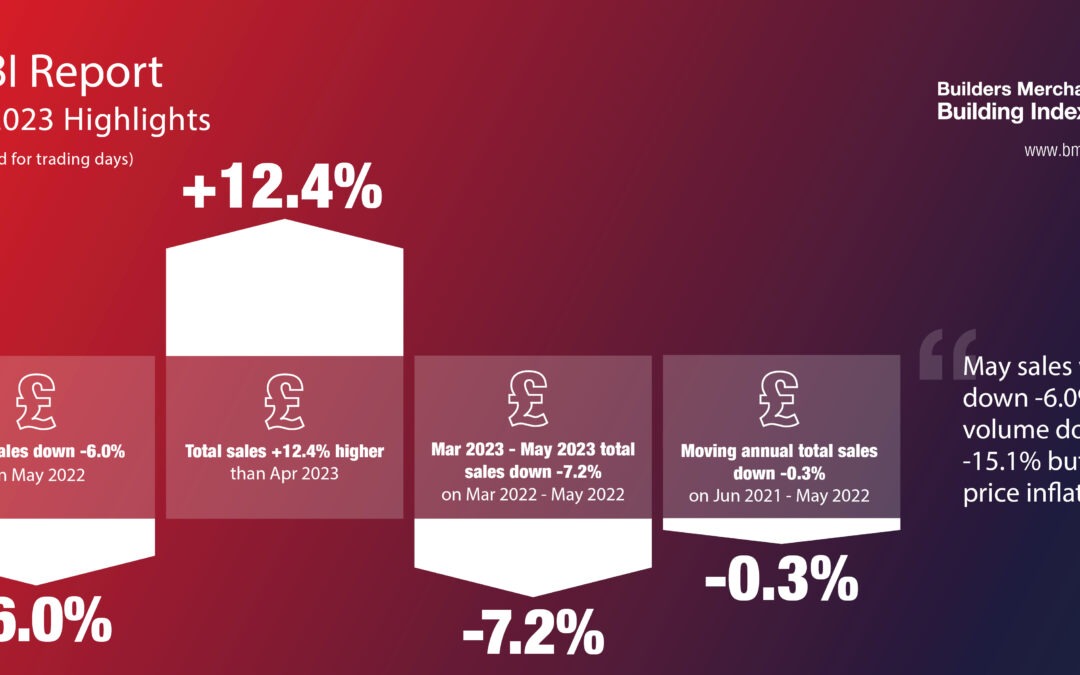

The latest Builders Merchant Building Index (BMBI) report shows builders’ merchants’ value sales down by -6.0% in May compared to the same month in 2022. Volume sales fell -15.1% with price inflation of +10.8%. With one less trading day in May 2023, like-for-like...

Recent Comments