Eaves Lintels

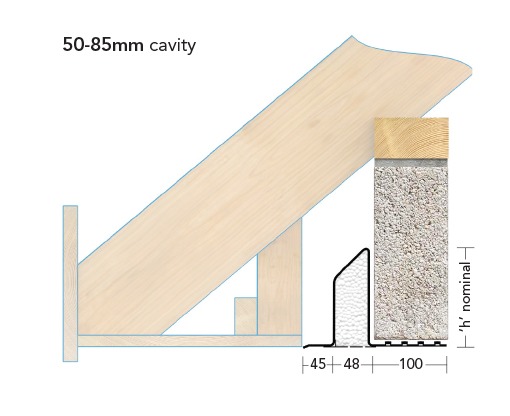

L1/E Steel lintels are designed to provide support over openings at eaves level. The eaves lintel has a shortened outer flange to allow the underside of the soffit board to be positioned tight against the window frame. It must be noted that brickwork cannot be built onto the outer flange of an eaves lintels. Masonry is built on the inner leaf only.

The loading figures are achieved by considering the lintel and masonry as a composite unit.

The lintel must have a minimum end bearing of 150mm on each side of the opening bedded on mortar. Level the lintel along its length and across its width. The lintel must be positioned to ensure that the masonry is built against the vertical upstand of the lintel. Masonry should be bedded on mortar and all perpendicularjoints filled with mortar.

A continuous timber wall plate must extend along the masonry immediately above the lintel. Lintel may be propped to facilitate speed of construction. A plaster key is incorporated into the inner leaf of the lintel.

The IG Eaves lintel also incorporates a thermal break plate on the underside of the lintel for superior structural performance.