Extended Range (L1/TJ)

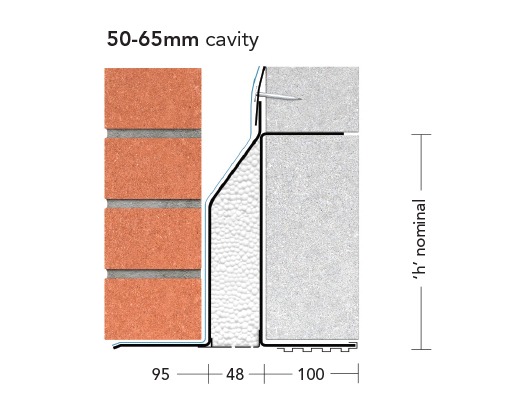

For standard loading conditions in 50mm wide thin joint cavity wall construction. To achieve loading figures lintels must be built in as shown with firmly butted perpendicular joints. The L1 /TJ lintel range can be supplied to suit wider cavities e.g. specify L1/TJ 70, L1/TJ 90. Lintels may be propped to facilitate speed of construction.

Thin Joint Lintels

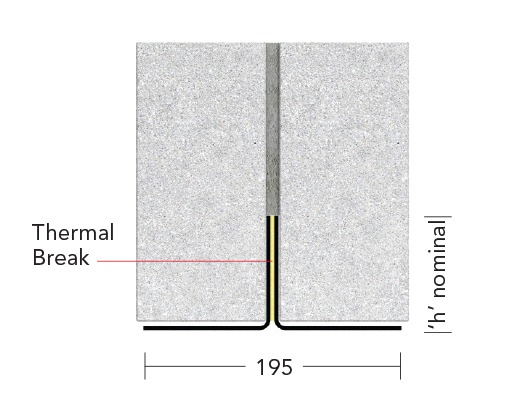

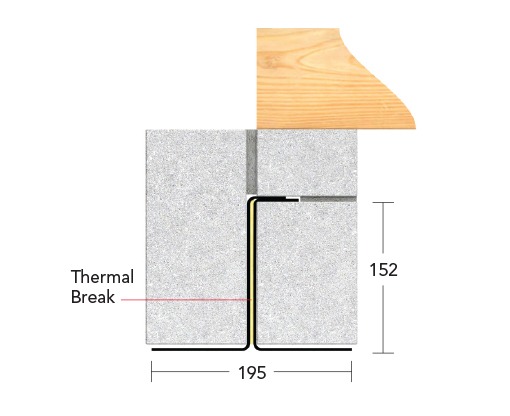

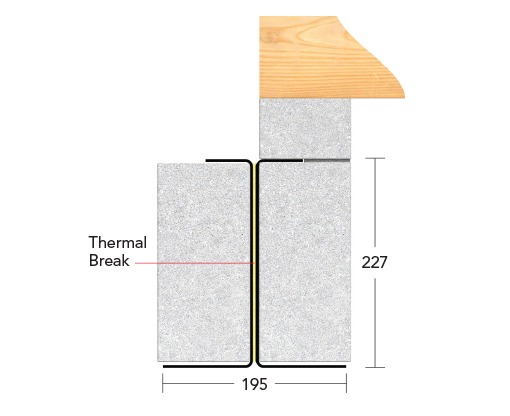

Designed for fast-track construction the thin joint lintel can be used as two separate lintels when the contractor chooses to build and complete the inner leaf of the building prior to starting the outer leaf. The “C section” is used for the inner leaf whereas the insulated angle lintel is used for the cavity and outer leaf. The Thin Joint Lintel must be used in conjunction with lateral restraint clips.

IG Thin Joint restraint clips are supplied free of charge and must be fixed to the blockwork by 3.3mm x 50mm galvanised nails. Allowance should be made for the movement of the entire structure due to settlement and shrinkage. Lateral restraint clip should be placed at 500mm centres each side of mid span.

The Thin Joint lintel is also recommended for thin mortar joint construction where joints are between 2mm and 6mm. This is particularly common when aerated blockwork is used.

Material

Thin Joint lintels are manufactured from pre-galvanised mild steel BS EN 10346:2009 DX51D plus Z600 or grade Z275 to BS5977: part 2, 1983 (BS EN 845-2:2003). There is a minimum zinc coating of 600g/m² galvanising including both sides. If stainless steel lintels are required IG utilise stainless steel grade 304 2b to BS EN 10088- part 2 Astm 240 (European Grade 1.4307). Thin Joint Lintels are insulated with expanded polystyrene and conform to BS 13163:2008.