Benefits

Better Buildability

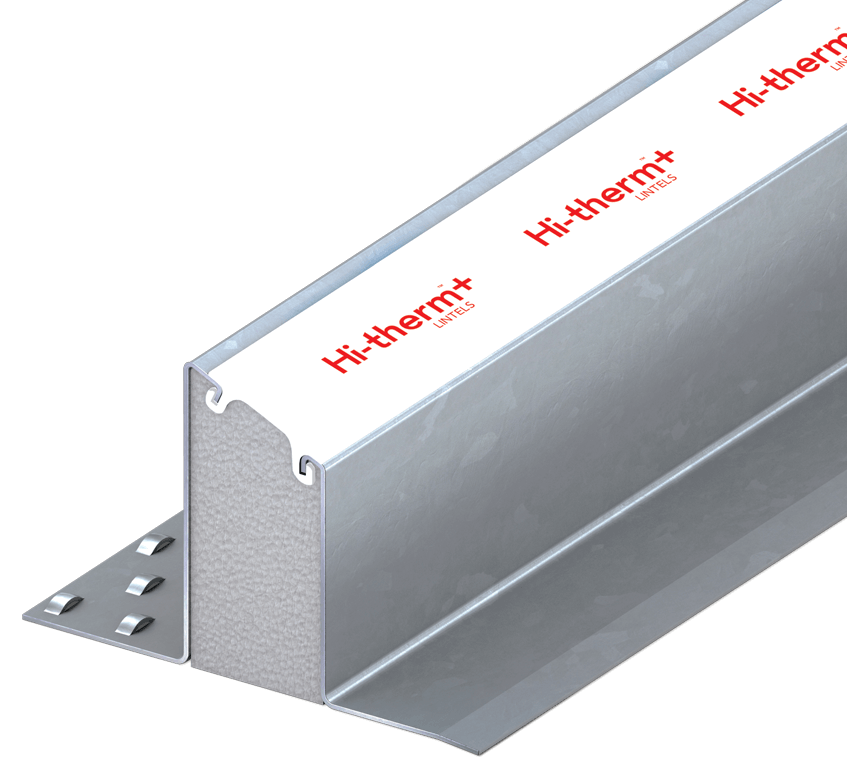

Better buildability – offers the simplicity of a one piece, structurally superior top hat design creating stability during the building process, unlike a two part lintel solution. Hi-therm+ is manufactured with a wider range & longer lengths. Learn more

Thermal Efficiency

Hi-therm+ is the only BBA Approved one piece lintel solution that achieves the appendix R value for steel lintels in Part L 2013, depending on wall construction. Up to 5 times more thermally efficient than a standard steel cavity wall lintel, therefore reducing thermal bridging & improving SAP calculations. Learn more

Cost Effective

A low cost route to improve both CO² reduction & Fabric Energy Efficiency standards, in line with Part L Building Regulations (see page 12 to compare Hi-therm+ cost efficiency with other popular alternatives). Learn more

Loading Tables

Cost Effective

Hi-therm+ offers a cost effective solution to lowering carbon emissions within SAP, offering significant savings compared to other popular alternatives.

In a comparative case study for a house type, using Hi-therm+ would incur less than 20% of the cost of increasing the cavity width by 50mm for the same saving in CO². These CO² savings are important within SAP because they give flexibility for compliance in situations where other built details are not meeting the standards in Appendix R.

Better Buildability

Maintenance free – No maintenance required unlike other sustainable technologies.

No DPC required up to areas classified as very severe by NHBC.

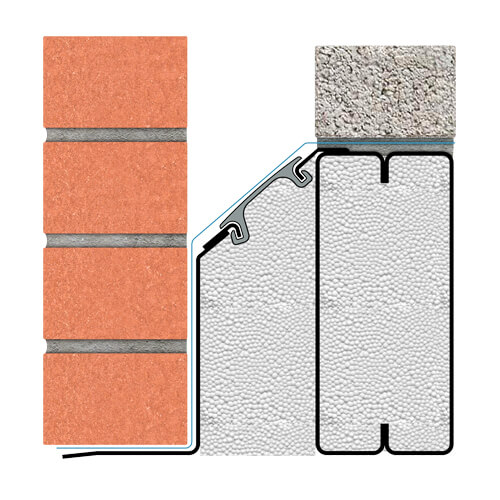

Split lintels – in some cases split lintels may be offered as a means of enhancing thermal performance however they are in no way comparable in terms of efficiency or buildability to the Hi-therm sustainability lintel.

Hi-therm+

- Hi-therm+ closes the cavity.

- The single component design simplifies installation.

- The one piece design assists stability between the internal and external leaves and creates stability during the build process.

- Hi-therm+ gives cost certainty with no additional costs.

Split Lintel

- A cavity closer must be supplied and fitted. ££

- Requires two separate lintels with double the handling and installation labour. ££

- Individual lintels will require propping and additional wall ties will be required to overcome the lack of inherent stability in a split lintel solution. ££

- ££ = Additional Costs.

New Barratt Homes

Sites throughout the UK.

Specifying Hi-therm significantly reduced thermal bridging on all house types.

“When the government unveiled its changes to Part L 2013 building regulations Barratts analysed a range of sustainable solutions in order to comply with the mandatory minimum fabric performance standard (Target Fabric Energy Efficiency, TFEE). The Hi-therm lintel has proved to offer a cost effective option as part of a suite of specification upgrades.”