Whytegates

Private Dwelling:

Products used:

Architect:

Contractor:

Whytegates

Brick Slip Feature Lintels

Stephen Langer Architects Ltd

Ascent Building Ltd

“For the detailing at Whytegates we specified three different forms of intricate curved brickwork, the semi-circular receding arch, circular windows and curved arch heads to all windows. This required a highly skilled level of brick cutting and craftsmanship, so the work done by IG to achieve our detail design aims has been highly successful.” – Stephen Langer, Stephen Langer Architects

Whytegates is a private dwellling of substantial character. Maintaining a traditional architectural style, the property exhibits distinct features reminiscent of the Arts and Crafts movement. Ascent Building Ltd would deliver the craftsmanship necessary to construct the intricate design utilising the highest quality building materials. IG were approached for the provision of feature brick lintels to help achieve the dwelling’s exterior facade. The modern building technique would accomodate the traditional character of the property, providing effective one-piece solutions for each decorative brick detail.

Challenge

Ascent Building Ltd was assigned with delivering the architect’s vision. The intricate brick detailing specified around the openings would require a great deal of skilled labour and brick cutting onsite if constructed using traditional methods. This would have been a time consuming task and required a high level of accuracy to ensure consistency across the brickwork.

Solution

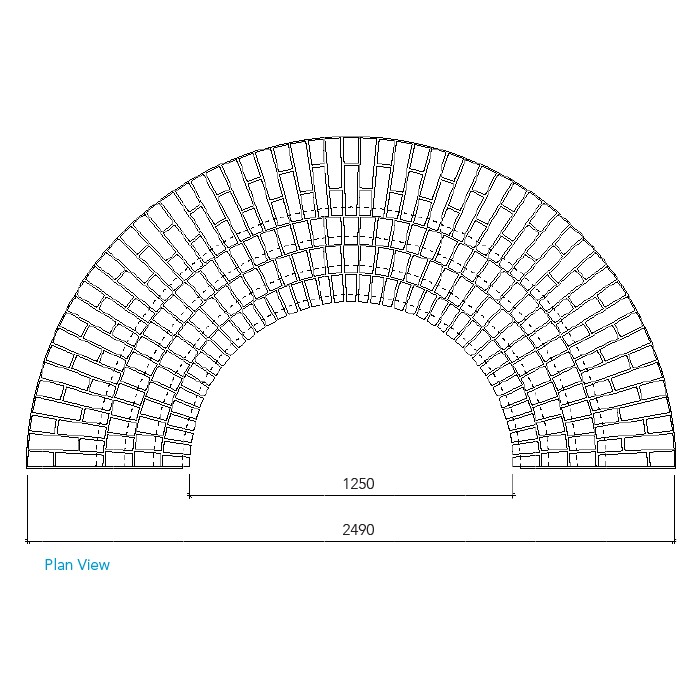

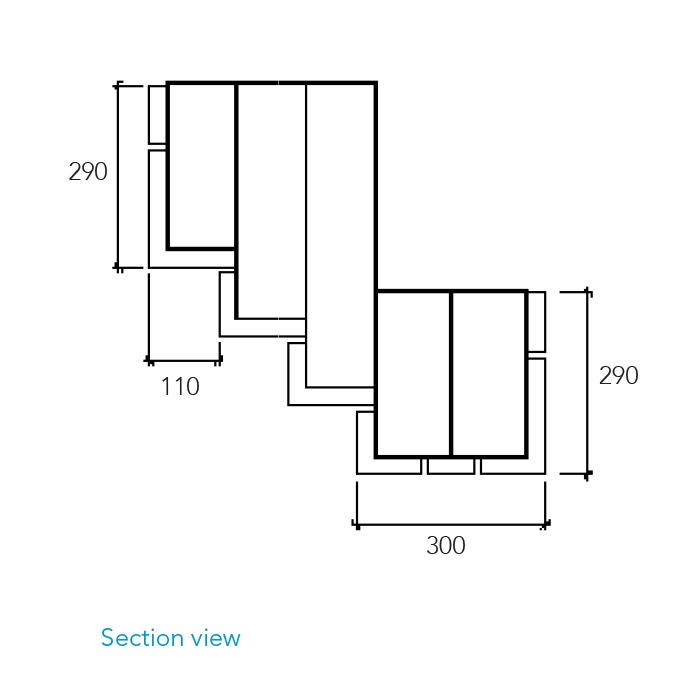

IG Brick Slip Feature Lintels offered an offsite solution which would achieve the decorative elements across the dwelling’s exterior façade. Manufactured bespoke to order, these brick feature components included a 2.4m span Corbelled Arch which defined the porch entrance to the property. This single piece unit saved Ascent Building significant installation time.

The level of quality control which could be achieved with these products was a major advantage for the architect as all the brick cutting and bonding took place in a controlled environment, free from wet weather, extreme temperature and excessive dust. IG collected a consignment of the brick being used on site and the brick feature units were delivered to site with bricks bonded, ready for installation and final pointing. This ensured that the arch blended seamlessly with already constructed brickwork. IG also supplied a range of other brick feature components including Flat Gauge Arches, Full Arch Lintels and Bullseye Lintels, all of which were manufactured bespoke to create the elaborate brick features on this stunning home.